Sul-Tower

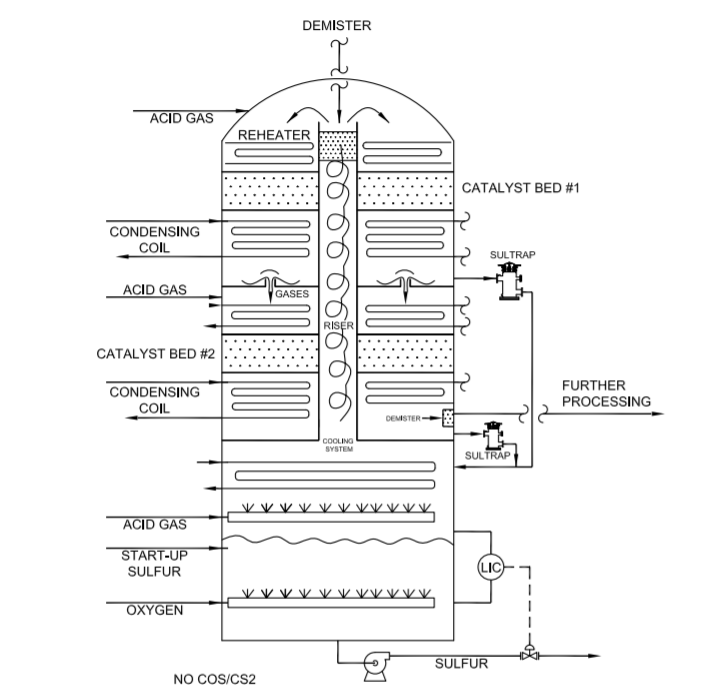

Sulfur Operation Support, Inc., is introducing the new SUL-Tower which incorporates a sulfur dioxide production tower with standard claus unit catalytic bed into a single vessel.

This revolutionary design will decrease plot space and overall cost of the standard claus train which utilizes several individual pieces of equipment into a single vessel.

The patent pending design uses a standard SO2 production whereby sulfur is produced in the bottom of the tower to make pure SO2 which can be used to injection into a standard design claus unit for capacity increase. SOS holds the patent on this technology for capacity increases in existing claus units.

This new configuration uses the same design for SO2 production whereby oxygen is introduced sub-liquid level of sulfur at prescribed temperature to combust/react the sulfur with oxygen (or air) to produce the high purity SO2.

In this design, the amine acid gas feed is introduced above the liquid level mixing with the high purity SO2. The combined feed gases start the claus reaction. The ratio is determined by the amount of acid gas and oxygen introduced into the tower.

The combined stream is cooled internally and flow upward through a riser. The reaction continues as the gas rises to the top of the tower. Once the flow reaches the tower head, the flow is reversed through a reheat phase and passes downward through the standard catalyst bed followed by a condensing section.

The sulfur is accumulated on tray and allowed to flow off the tray through SulTrap. The unreacted gases continue the downward flow through a capped pipe into the second reaction system which includes another reheat, catalyst bed and condenser. Again, the sulfur is collected and allowed to pass through a SulTrap in a pit or back into the liquid level of the tower.

Both the above beds have slip stream of acid gas feed to adjust the ratio of the sulfur dioxide and hydrogen sulfide.

Calculated efficiency is approximately 95% or higher depending on the acid gas feed. Final efficiency is expected to be higher.

This system eliminates the thermal reactor along with all the issues of the refractory and elevated temperature experienced on the tube sheet of the WHB which is also eliminated.

The cooling phase and resulting riser acts at the first condenser prior to entering the first catalytic section. The final heat balance is determined by compositions of acid gas and resulting sulfur production. This determines how much of the produced and collected sulfur is directed back into the base of the tower.

Down stream processing of the tail gas can be minimized by adjusting the H2S/SO2 ratio in the last bed. This adjustment along with an additional bed can result in minimum or no hydrogenation reactor requirement.

CONTACT INFO

Sulfur Operations Support, Inc.

PO Box 1770

Ocean Springs, MS 39566

228-875-5515

Questions regarding sales?

sales@sultrap.com

Technical questions?

SOS Informational Packet